Part of Your Winning Team

At Technique, our clients are more than just chassis templates. We become a part of their teams the instant they contact us. We bring our unique team atmosphere to you, providing on-site support and analysis from experienced professional racers. Our pros have a greater understanding of your needs and help us develop the best, most efficient chassis components -components that you can trust to put into your cars that run on the race track.

The Winning Process

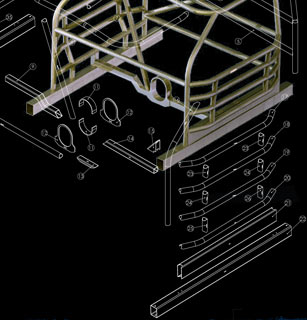

It starts with a meeting between our staff and your team to determine the strict specifications you require in your chassis components. As experts of bending, forming and laser-cutting chassis components, we create your parts with the utmost precision and ease of replication. We then continue to use the best precision laser-cutting tools in the industry to create natural weld fillets on your tubing to assure stronger welds. Once manufactured, we meticulously verify the precision of each build by using industry-leading, laser-guided inspection equipment, because we know the eighth of an inch can be the difference between driving to victory lane and heading to the garage.

When Time Matters Most

Technique Engineered Chassis Components are ready-to-assemble, featuring easier-to-complete welds and more precise fittings to help your team build a better chassis much faster. In an industry where one-hundredth of a second is the difference between jubilation and disappointment, time is everything, and build time in the garage is as critical as speed on the track. At Technique, our race-proven experience and our winning process can save you 30% on build time as well as 30% in labor costs. We also provide an updated CAD model which helps estimate weight and prepare for future development, in a fraction of the time. After all, more time saved in the garage translates into more time on the track.